ASME BPE (Bioprocessing Equipment) standards define specific surface finish requirements for components used in biopharmaceutical and others to ensure cleanliness and sterility. These standards, ranging from SF0 to SF6, dictate the smoothness and preparation of surfaces to minimize particle and bacterial retention. SF1 and SF4 are commonly used, with SF1 being mechanically polished and SF4 being electropolished, both meeting stringent roughness requirements.

ASME BPE Surface Finish Designations:

- SF0 - SF6: A series of surface finish designations, with lower numbers indicating smoother finishes.

- SF1: Mechanically polished, with a maximum Ra value of 0.51 µm (20 µin).

- SF4: Electropolished, with a maximum Ra value of 0.38 µm (15 µin).

- Other designations (SF0, SF2, SF3, SF5, SF6): Available for specific applications.

- Other designations (SF0, SF2, SF3, SF5, SF6): Available for specific applications.

Key aspects of ASME BPE surface finish standards:

- Smoothness:The standards ensure surfaces are smooth to reduce areas where bacteria or particles can accumulate.

- Material Selection:ASME BPE specifies the use of high-quality stainless steels, like 316L, with controlled sulfur content to minimize corrosion and ensure long-term performance.

- Traceability:ASME BPE-certified components are marked and labeled for full traceability, allowing for easy audits and inspections.

- Compatibility:The standards ensure compatibility with sterile processes and facilitate cleaning and sterilization procedures.

Importance of ASME BPE Surface Finishes:

- Product Purity:Smoother surfaces reduce the risk of contamination and ensure product purity in sensitive applications.

- Sterility:The standards are critical for maintaining sterility in bioprocessing and pharmaceutical manufacturing.

- Regulatory Compliance:Adherence to ASME BPE standards ensures compliance with industry regulations and best practices.

Why smooth surfaces matter

The smoothness of stainless steel surfaces is crucial in bioprocessing equipment due to several factors:

Contamination Control: Smooth surfaces reduce the potential for particles and bacteria to adhere to the equipment, which can lead to contamination of the product.

Ease of Cleaning and Sterilization: Smoother surfaces are easier to clean and sterilize, which is vital for maintaining a hygienic processing environment.

Prevention of Biofilm Formation: A smooth surface minimizes the creation of areas where bacteria can colonize and form biofilms, which are a major concern in bioprocessing. Why smooth surfaces matter

The smoothness of stainless steel surfaces is crucial in bioprocessing equipment due to several factors:

Contamination Control: Smooth surfaces reduce the potential for particles and bacteria to adhere to the equipment, which can lead to contamination of the product.

Ease of Cleaning and Sterilization: Smoother surfaces are easier to clean and sterilize, which is vital for maintaining a hygienic processing environment.

Prevention of Biofilm Formation: A smooth surface minimizes the creation of areas where bacteria can colonize and form biofilms, which are a major concern in bioprocessing.

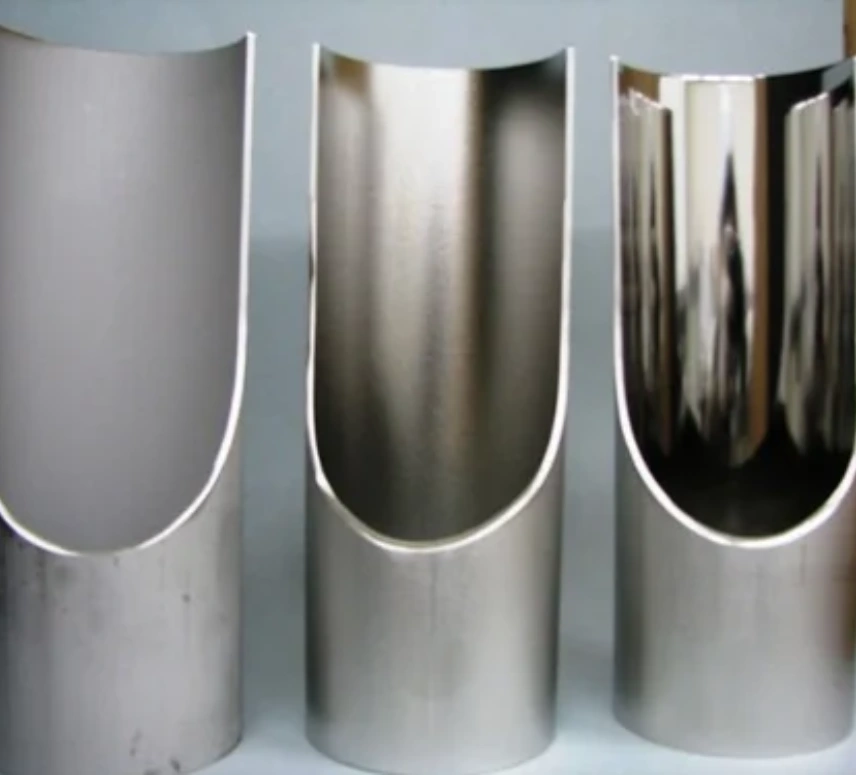

Material and treatment considerations 316L Stainless Steel: Widely used in the pharmaceutical industry due to its corrosion resistance, durability, and compatibility with various products and sterilization processes. ASME BPE specifies chemical composition requirements for 316L, including controlled sulfur content to enhance weldability and reduce inclusions. Mechanical Polishing: Involves abrasive grinding and buffing to achieve the desired Ra value. Electropolishing: An electrochemical process that removes surface material and imperfections, leaving a smooth, passive, and highly corrosion-resistant surface. It preferentially removes iron and surface contaminants, enriching the surface with chromium and forming a thicker, more uniform oxide layer. Passivation: A chemical treatment (typically using citric acid) that removes free iron and other contaminants from the stainless steel surface, enhancing corrosion resistance. It's crucial for maintaining the integrity and performance of the equipment, especially after fabrication or repair.